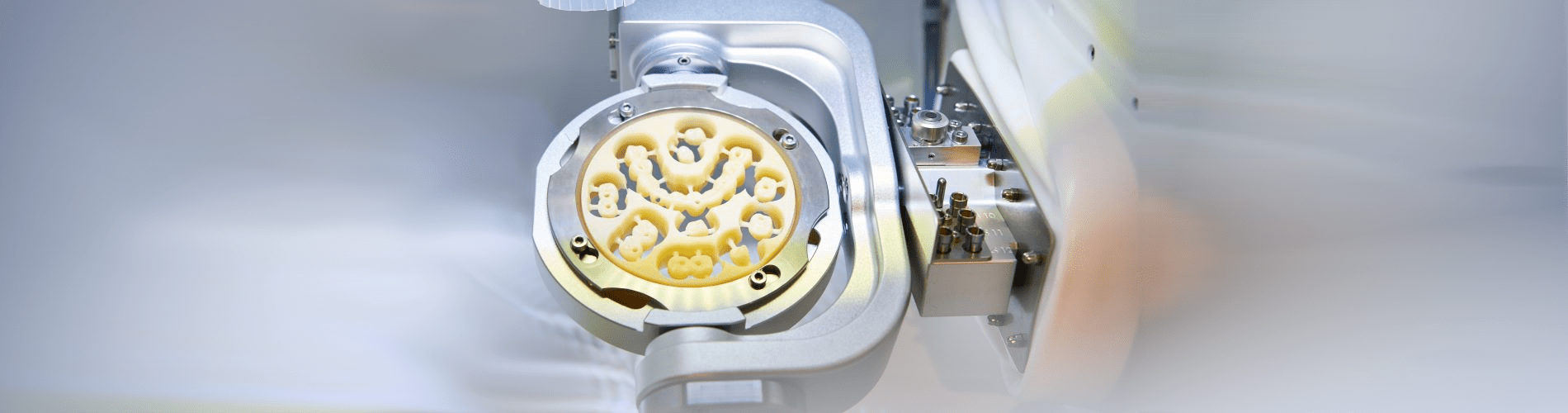

CAD/CAM Refill-Material

for CAD/CAM milling crowns

High-end denture base material with patented polymer composition for refilling CAD/CAM milling blanks and for fabricating customised blanks.

Product details

Indications:

- Fabrication of crystal-clear and coloured occlusal splints using the CAD/CAM process

- Fabrication of denture bases using the CAD/CAM process

- Fabrication of crowns and bridges using the CAD/CAM process

- Filling of milling fronts using the CAD/CAM process

Processing:

- Mixing ratio: 10 g powder with 5 - 6 g liquid

- Swelling phase: approx. 30 seconds

- Pouring phase: approx. 2-3 minutes

- Swelling phase before polymerisation: min. 5 minutes

- Polymerisation (2 - 3 bar, 55 °C): approx. 20-30 minutes

Features:

- universal application, can be used for refilling all PMMA blanks

- very easy processing, optimum cutting behaviour during milling

- minimal shrinkage, no tension within the material thanks to controlled polymerisation

- Optimum mucous membrane compatibility due to low residual monomer content

- easy to finish and polish

- homogeneous surface, very low plaque susceptibility

- absolute colour stability thanks to a catalyst system without tertiary amines

- Tested and certified biocompatibility

- Phthalate, BPA and cadmium free

Colours:

The material is available in crystal clear, light pink, light pink veined, pink, pink veined, pink opaque. Can be coloured individually with retec® SIN COLOR. Special colours on request.

Dosage forms / packaging:

Powder: 500 g, 1,000 g, 5 kg, 10 kg

Liquid: 500 ml, 1,000 ml, 5 L

We supply both finished products and partially customised goods according to your specifications and wishes. Other delivery quantities, e.g. bulk packs, on request.

Note: Medical device. Classification in accordance with the product standard for denture acrylics, DIN EN ISO 20795-1, type 2 class 1 and in accordance with MDD 93/42/EEC Annex IX, class IIa for removable and fixed dentures.